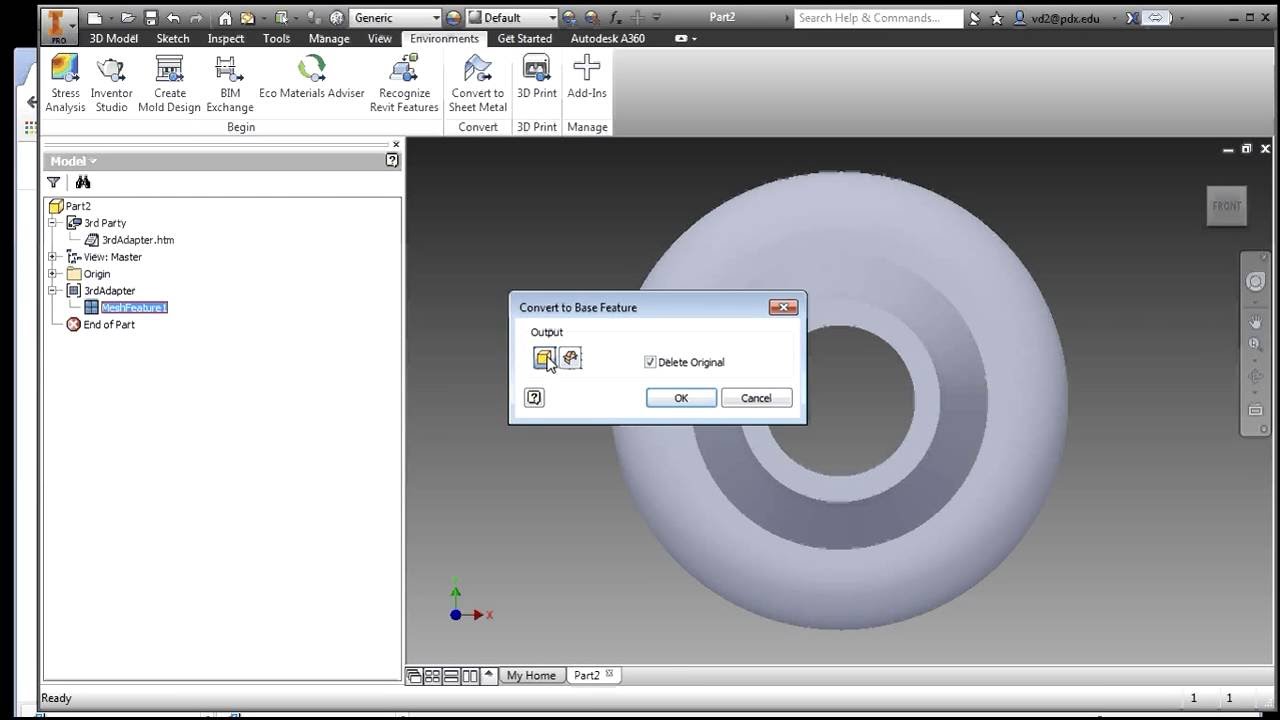

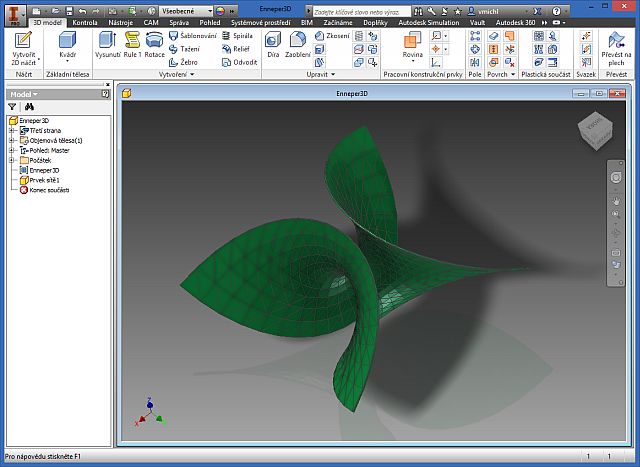

Use a different extension to collaborate About Importing Files from other CAD Systemsįrom version 2021 there is a link between Revit and Inventor data with An圜AD for seamless interoperability. Autodesk does not recommend the use of one over another, nor guarantee their successful operation. These 3rd party converters can be found on the Internet. The Mesh Enabler converts mesh features to solid base features or surface features and can be applied. Then import it into Inventor as a surface, stitch it, and convert it to solid, or work with the imported surfaces. The Mesh Enabler is an add-on for Autodesk Inventor. Use 3rd party converters There are also 3rd party products that you can use to convert the STL file to a different format.

, but It was STL file so if I want to modify it, I have to convert STL file to 3D model. I also needed pan-tilt mount, I downloaded similar model from “” It will be 3d printed and the design should be added hole for the bolt to be fasten well I changed design for the lens.īall joint : I made ball joint to connect aluminium pipe and camera mount. Second mistake : Gopro case cannot be assembled with Gopro because of the lens. If I used parametric properties when I made dimensions, I could save much times. I measure the size of Gopro case from the STL file I downloaded (link : ) but It was Gopro1. I needed to change the angle.įirst mistake : The biggest mistake I made was that the Gopro case was not fit in my Gopro model. It looked like belowīut the angle of the camera mount was limited to see downward. I assembled all the file I downloaded, and modified the size to servos fit into the mount.

I downloaded GoPro and servo motor models. there are many servo motor’s CAD model files on internet. I’m going to model a Gopro 3D mount with pan-tilt motion.

Inventor mesh enabler software#

I downloaded the free student software from the autodesk website. because I wanted to try that I haven’t used it before. I decided to using Autodesk Inventor for this assignment. It will be 3D printed and assembled with 2 Gopro cameras, 2 Servo motors, 1/2 inch diameter aluminium pipe. I modeled a part of my potential project (Real life game with third person view). I modeled and rendered with Autodesk Inventor. I have a experience with a SolidWorks and Sketchup. On this week, the assignment was to model(draw, render, animate, simulate.

0 kommentar(er)

0 kommentar(er)